Created a Line of Tools

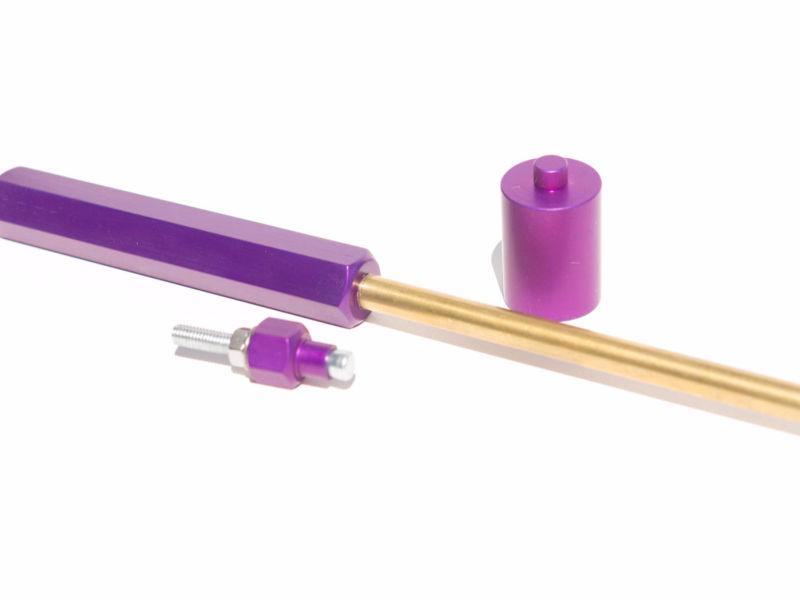

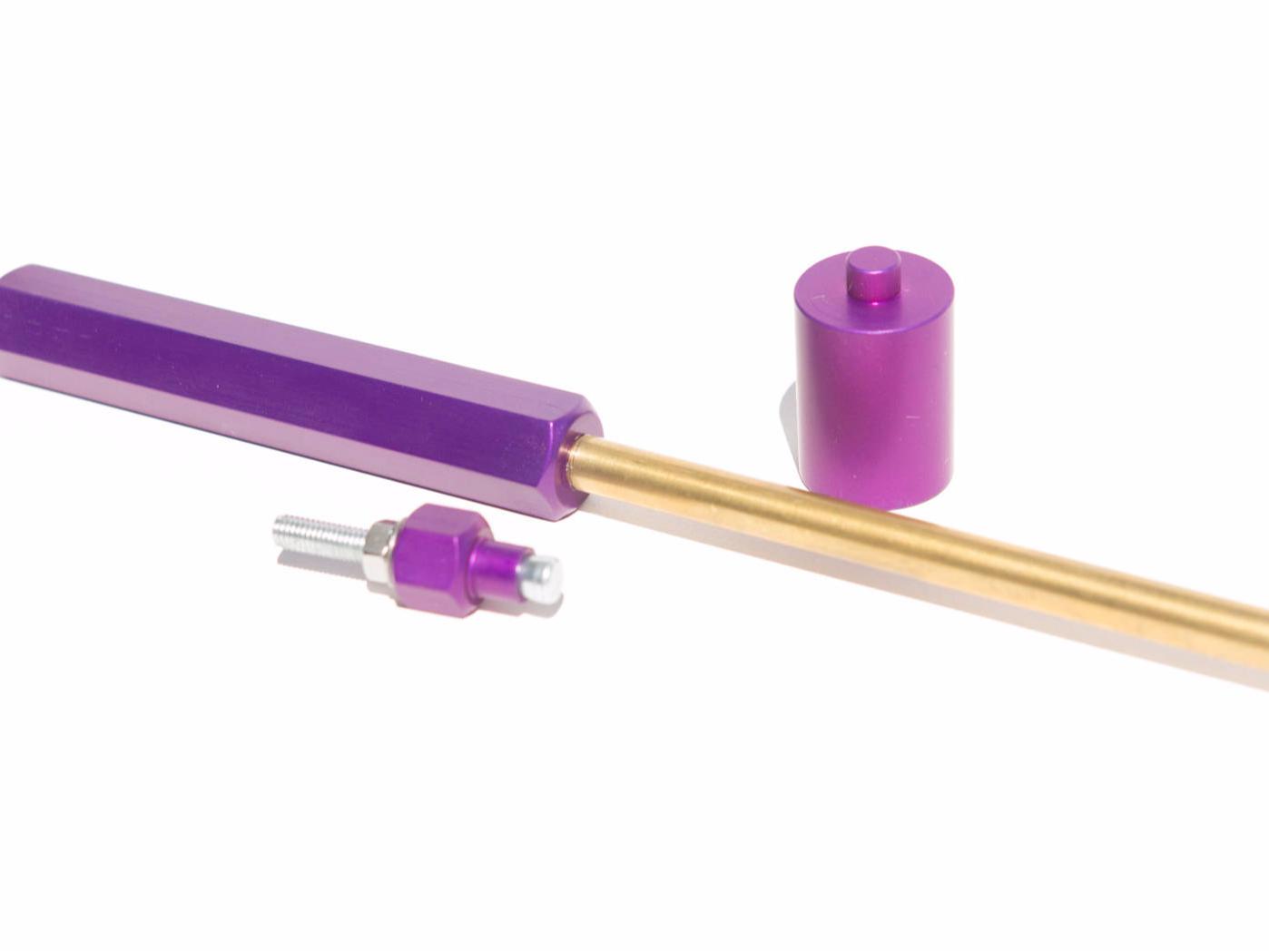

After lots of testing, we created three types of tools for the front casters, forks and rear wheelchair wheels: Brass Pin Punch, Blind Bearing Extractors and Bearing Press for large bearings and punch blocks for smaller ones.

Design and Prototyping

The first tool was a brass pin punch. Most punches are made of steel which can damage the bearing or hub and they have a very short nose so you cannot reach down into a wheelchair hub. The second was a blind bearing extractor. This came from the bike world but we made it longer to reach into a wheelchair hub or fork. The third was a line of bearing installers. For smaller bearings, round a front caster, we made small cost-effective punch blocks used with a hammer. For more larger bearings found in the forks and rear hubs, we made a bearing press.

Machining and Finishing

Several designs were made and refined. Then we develop a production process, warehousing and pick and pack so we could drive the company behind Wheelchairbearings.com.